The National Healthcare Innovation & Productivity (NHIP) Medal is an annual event organised by Centre of Healthcare Innovation. It serves to recognise, celebrate, and acknowledge the excellence of innovation & productivity in the healthcare system.

ST Healthcare (STHC) is proud to be awarded the Best Practice Medal (Automation, IT and Robotics Innovation category) with our project titled “Building a sustainable and resilient value-based supply chain through innovative models and technology advancements”.

This collaborative project with Tan Tock Seng Hospital started with the intent to improve the existing supply chain processes in the hospital. Over time, their supply chain capabilities have been elevated and transformed to the next level, bringing more value and outcomes to healthcare staff and patients. With their upcoming plans for Novena Health City in 2030, a highly effective, robust and scalable supply chain resilience model is in place for both routine and emergency situations.

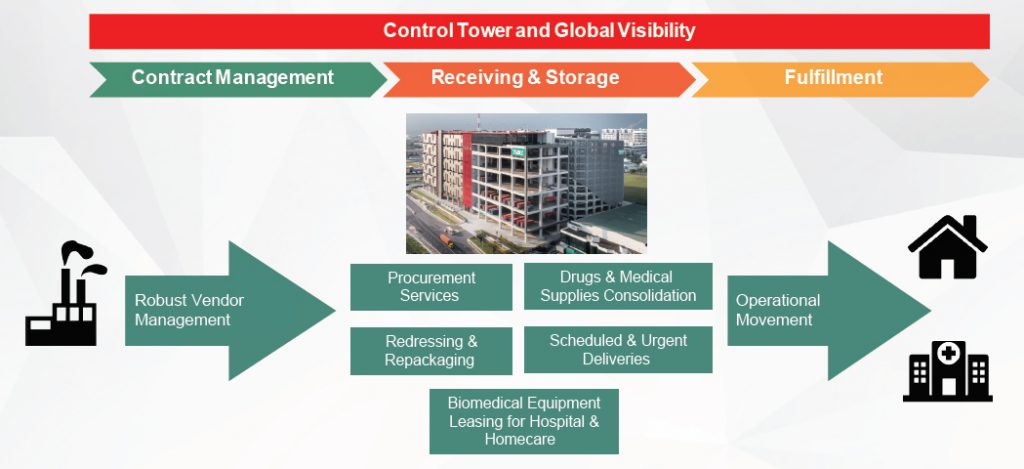

STHC’s strategy in redesigning TTSH’s supply chain:

Result & Benefits

The strategy was successful, and proved that a vendor could support their medical consumable needs from an off-site facility.

With these strategies in place to ensure a robust supply chain for TTSH, benefits for both parties are aplenty – reduction in manpower, reduction in administrative work, ability to cater for surges and expansion, the transfer of risk and inventory holdings to the vendor, data analytics and tightened security to name a few.

STHC believes constant innovation is crucial to futureproof operations and the workforce, and transform the healthcare supply chain.